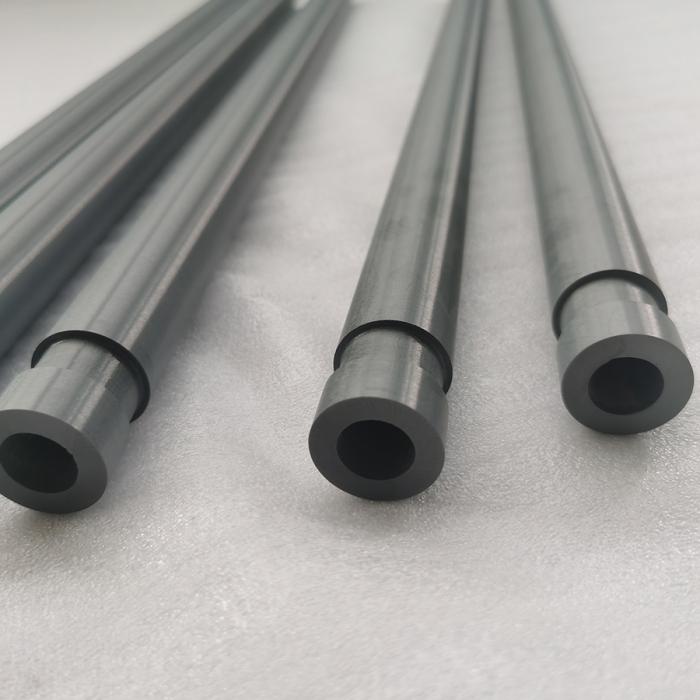

THE OPERATING MANUAL OF CERAMIC RISER TUBES

1. Storage and Carrying

Fragile!Handle with Care. Avoid to be shocked by external force. Avoid to be stored in the excessively wet environment.

2. Installation

Install the iron flange outside and keep the mounting surface flatly which maybe destroy the corresponding parts of the ceramic riser tube. Please choose the suitable gasket and keep the surface of the riser tube lower than the flange 1-2mm after installing.

3. Using

Firstly, install the tube on the machine and don't insert it in the molten aluminum directly. Otherwise, it maybe make the tube crack or make the aluminum liquid-cooled burst out form the nozzle.( Any riser tubes of different materials all possibly happen). So please preheat the tube about 20 minutes in the furnace atmosphere and then inject the molten aluminum.If the tube is red hot, please wrap it with the thermal insulation blanket immediately when taking it out from the machine. And pay attention to the personal safety. When replacing the mould each time, please remove the attached aluminum at the nozzle with the prod and hammer softly to avoid pressing the portal next time.4. Notice

Avoid giving mechanical shock on tube. No hammering is allowed and adhered aluminum on tubes should be removed by scraping or grinding.

No preheating on drying process before usage and on starting operation are required Immerse slowly into liquid after wiping off water on tube surface.

Partial heating by burner or rapid cooling by water should be absolutely avoided in order to minimize thermal shock. Partial abrupt thermal shock causes breakage of tube.